Before setting or using Tohatsu springs, please read the Instruction manual and keep it by yourself.

When using or setting springs, please adhere to the following guidelines. The indication and meaning of this text are as follows.

Failure to adhere to this text could result in the danger of serious accident or human injury during manufacture due to scattering or broken springs.

Failure to adhere to this text could result in damage to spring and inplement of periphery.

Points to understand when using these products.

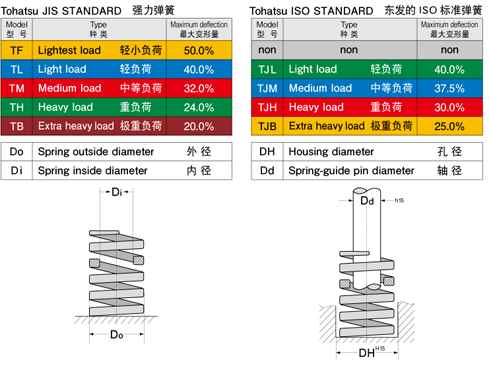

■Confirmation of product standards

Before the setting or utilization of the springs, please take good note of the specifications at the top of the plan and installation product standards. (Please note in particular that the identification colors and spring characteristics of “ISO10243 Standard” and “JIS B 5012 standard” differ according to product.)

□Re-enforcement of mounting part

Springs are made from hard steel. This characteristic means that parts applying or receiing pressure

from the spring may begin to flake due to abrasion during use. Please take measures to protect and

re-enforce parts above and below the spring.

□Periodic inspection

Weakening of the product will occur in accordance with the frequency of use, please replace the spring when necessary. Please perform inspections to ensure that the product is always treated with an adequate

level of anti-rust machining lubricant. Please note that "Uncoated, MR, LR, Other springs (not designated as

anti-rust treated)" are not coated by anionic electro-deposition and so are particularly susceptible to rust.

□Storage

Please store in a safe place that is free from humidity and high temperatures and do not allow other people to handle.

□Disposal

Tohatsu springs are made from steel alloys (silicon crome steel used for springs, piano wire, stainless steel

wire for springs) and so can be disposed of in the same manner as regular scrap metal. Customers who have

special conditions related to the disposal of coated materials should refer to page 8 or contact us for advice.

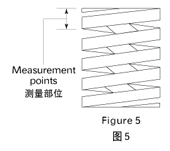

○Outside and Inside, diameters

○Outside and Inside, diameters

Spring dimensions are measured from the 1st or 2nd coil from the spring’s end section (see figure 5).

○Spring constants

Guidelines for load calculations for deflection rates

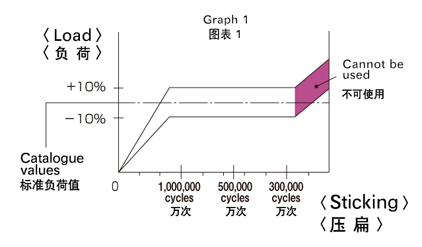

○Load characteristics

There may be instances wherein the actual load values fall outside the allowable load variance with the load at a low level and at a high level as the load nears the maximum deflection rate (sticking) in relation to load calculation values with strong spring fixed numbers (refer to graph 1).

○Identification colors

Even when the identification colors are the same standard loads and standard dimensions may vary. Please take good care when selecting springs.